Effective Material Transport: Locate the Suitable Stacking Conveyors for Sale Today

Effective Material Transport: Locate the Suitable Stacking Conveyors for Sale Today

Blog Article

Increase Recycling Performance With Stacking Conveyors: a Total Equipment Guide

Advantages of Stacking Conveyors in Recycling

Stacking conveyors supply various benefits in the reusing industry, boosting effectiveness and decreasing labor costs. Among the crucial benefits of utilizing piling conveyors in recycling is their capability to increase throughput. These conveyors are created to handle big amounts of materials, permitting a continuous circulation of recyclables throughout the sorting procedure. By eliminating the requirement for manual handling and transport of products, stacking conveyors improve the reusing process, lowering downtime and enhancing performance.

Another benefit of piling conveyors is their adaptability. These conveyors can be tailored to fit the particular needs of a recycling center, whether it be a large facility or a small operation.

In addition, stacking conveyors add to a safer working atmosphere. By automating the activity and handling of materials, they minimize the threat of manual labor-related injuries and mishaps. This not just protects the wellness of employees however also decreases the prospective prices related to work environment injuries.

Kinds Of Piling Conveyors for Recycling

One important consideration when executing stacking conveyors in a recycling facility is the choice of the proper kind of conveyor for the details demands of the procedure. There are several types of piling conveyors that are generally made use of in reusing centers, each with its very own special functions and advantages.

The first kind is the radial piling conveyor, which is developed to rotate around a main pivot point. This allows for better adaptability in terms of stockpiling products, as the conveyor can be gotten used to produce a radial accumulation in any direction.

One more kind is the telescoping conveyor, which can be prolonged or retracted to get to different sizes. This is especially useful in recycling centers where area is restricted, as the conveyor can be gotten used to fit within the available location.

Additionally, there are additionally fixed-length stacking conveyors, which are created to have a particular length and can not be changed - stacking conveyors for sale. These conveyors are typically used in applications where a constant stockpile size is called for

Lastly, there are tracked stacking conveyors, which are installed on tracks or wheels. This enables very easy movement and positioning of the conveyor, making it excellent for recycling centers that require constant moving of tools.

Elements to Take Into Consideration When Choosing a Stacking Conveyor

When picking a piling conveyor for a recycling facility, it is important to thoroughly take into consideration various aspects to make certain optimum efficiency and effectiveness. Among the critical variables to take into consideration is the sort of product being taken care of. Various products have different characteristics such as dimension, shape, and weight, which can impact the choice of piling conveyor. If the facility bargains with heavy products such as metals or aggregates, a sturdy and robust piling conveyor with a high load capability would be needed.

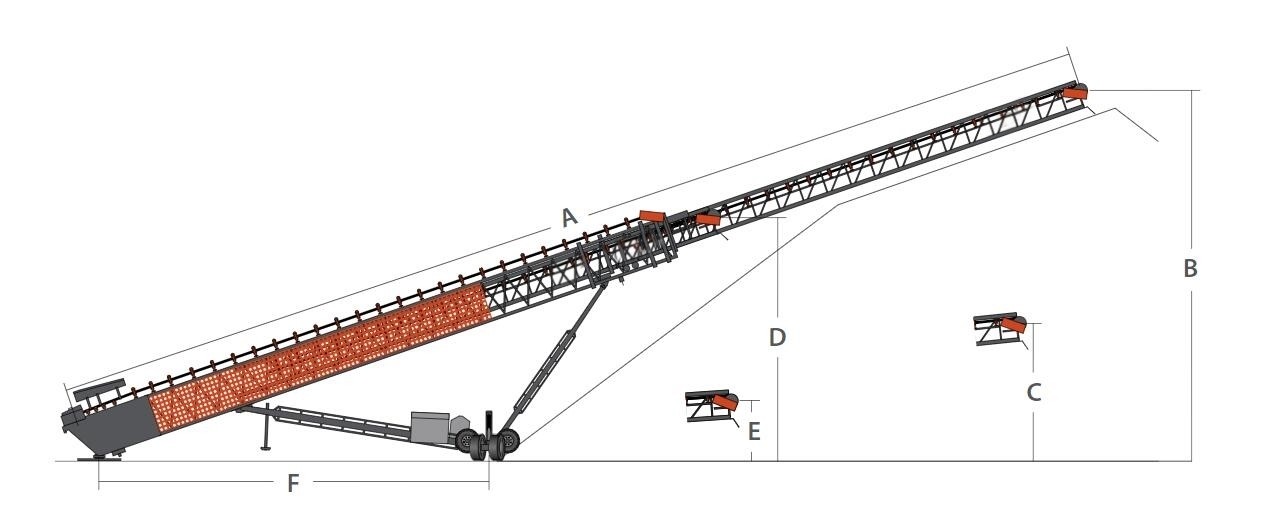

One more crucial aspect to take into consideration is the required stacking height. The stacking conveyor ought to have the capacity to reach the preferred height without jeopardizing stability or safety. Furthermore, the length and size of the stacking conveyor should be ideal for the available space in the center. stacking conveyors for sale. It is important to make sure that the conveyor can be quickly navigated and positioned within the facility.

The rate and capability of the stacking conveyor are additionally crucial considerations. The conveyor ought to be able to manage the necessary quantity of material efficiently, without creating any type of jams or disruptions in the reusing process. The conveyor must have flexible speed setups to accommodate different handling requirements.

Lastly, this article the durability and upkeep needs of the stacking conveyor needs to be considered. It is suggested to select a conveyor that is made from high-quality products and is made for durable usage. Additionally, simple upkeep and access to spare components are essential aspects to consider to decrease downtime and keep the recycling facility running smoothly.

Setup and Upkeep Tips for Stacking Conveyors

To ensure ideal performance and durability of stacking conveyors in a recycling center, proper installment and maintenance are crucial elements of their effective operation. In addition, proper placement of the conveyors is vital to guarantee smooth product transfer and protect against any type of possible damage to the devices.

Normal maintenance is additionally important to maintain stacking conveyors running effectively. This consists of regular examinations to identify and address any indications of wear and tear, find more information such as broken belts or rollers (stacking conveyors for sale). Lubrication of relocating parts should be performed on a regular basis to decrease friction and protect against early failure. It is additionally vital to maintain the conveyors complimentary and clean from any debris or impurities that can conflict with their operation.

Moreover, having a positive maintenance timetable, consisting of routine servicing and replacing damaged elements, is crucial to reduce and avoid unanticipated malfunctions downtime. Educating staff on appropriate procedure and maintenance procedures is just as essential to make sure safe and efficient handling of the tools.

Making Best Use Of Efficiency With Stacking Conveyors in Recycling

Stacking conveyors play a critical duty in making the most of effectiveness within recycling centers. These effective makers are made to transport and pile numerous products, such as recyclable waste, in an arranged and reliable way. By using stacking conveyors in recycling operations, centers can streamline their procedures, boost efficiency, and decrease labor costs.

Among the vital advantages of stacking conveyors is their capacity to develop stockpiles of different products. This removes the requirement for manual arranging and storage space, as the conveyors can immediately deposit the materials in marked locations. This not only conserves time but also lessens the risk of contamination or damages to the recyclable materials.

Piling conveyors likewise contribute to a much safer working environment. By automating the activity and stacking of products, workers are much less revealed to prospective hazards, such as heavy training or slipping. This not only lowers the danger of More Bonuses crashes however additionally improves general performance by allowing workers to concentrate on other tasks.

Conclusion

Finally, piling conveyors play an essential function in improving recycling performance. With their capability to effectively transfer products and their adaptability in dealing with numerous sorts of recyclables, piling conveyors are a beneficial asset in the reusing industry. By taking into consideration aspects such as conveyor maintenance, setup, and kind, reusing facilities can maximize the effectiveness and performance of their procedures. Stacking conveyors provide an efficient remedy for improving advertising and recycling processes sustainability.

When selecting a piling conveyor for a reusing facility, it is vital to thoroughly think about various elements to make sure ideal performance and performance.To make certain ideal performance and longevity of piling conveyors in a reusing facility, correct installment and maintenance are vital components of their effective operation.Stacking conveyors play a crucial function in making the most of efficiency within reusing facilities. By making use of piling conveyors in recycling procedures, centers can streamline their procedures, improve performance, and decrease labor prices.

With their ability to successfully carry products and their adaptability in managing various kinds of recyclables, piling conveyors are an useful property in the recycling market.

Report this page